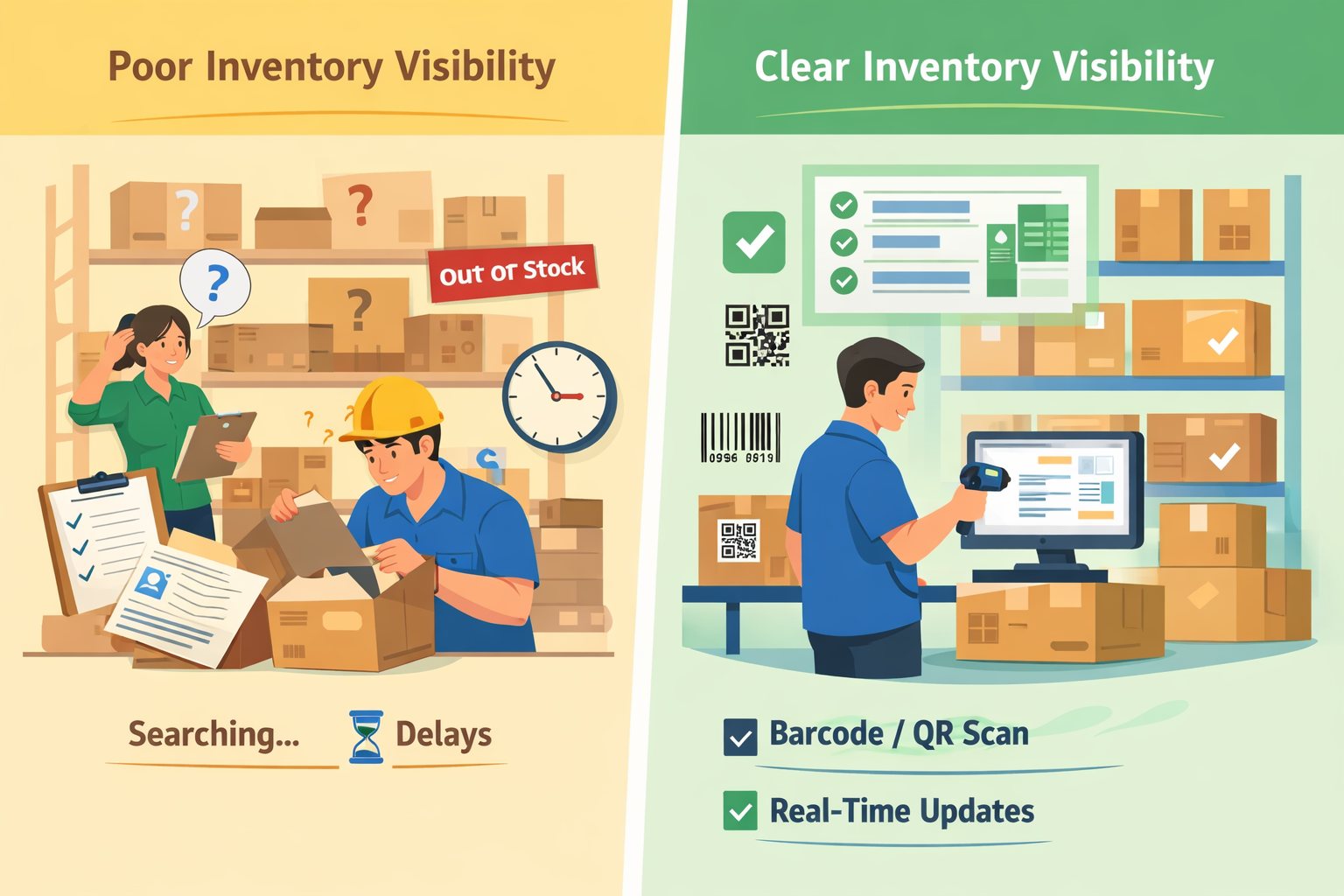

In many businesses, inventory problems don’t always start with missing items. They start with poor inventory visibility.

When teams don’t clearly know what items they have, where those items are, or how many are available, daily work slows down. Staff waste time searching, tasks get delayed, and decisions are made based on guesses instead of accurate data.

This may seem like a small issue at first, but over time, poor inventory visibility affects productivity, costs, and overall operations.

What Is Inventory Visibility?

Inventory visibility simply means having a clear and up-to-date view of your inventory.

It answers basic but important questions like:

- What items are currently available?

- Where are they stored?

- How many are left?

- Who is using them?

- When were they last moved or updated?

When these answers are not easily available, daily operations become difficult.

How Poor Inventory Visibility Slows Down Daily Work

1. Time Is Wasted Searching for Items

When inventory is not properly tracked, employees spend a lot of time opening boxes, checking shelves, or asking others where an item is kept.

This slows down routine tasks and reduces productivity.

2. Work Gets Delayed

If teams are unsure whether an item is available or already in use, tasks are delayed.

This is common in offices, warehouses, healthcare facilities, and maintenance teams where equipment and supplies are shared.

3. Overordering and Shortages

Without clear visibility, businesses often:

- Order items they already have

- Run out of important supplies unexpectedly

Both situations lead to unnecessary costs and operational stress.

4. No Clear Accountability

When inventory movement is not recorded, it becomes difficult to know:

- Who used an item

- When it was taken

- Whether it was returned

This increases the chances of misplaced or lost assets.

5. Poor Decision-Making

When inventory data is unclear or outdated, decisions are based on assumptions instead of facts.

This affects purchasing, planning, audits, and daily management.

How to Fix Inventory Visibility Issues

The good news is that poor inventory visibility can be fixed with the right approach.

Move from Manual Tracking to Digital Tracking

Spreadsheets, notebooks, and memory-based tracking make it hard to maintain accurate records.

A digital inventory system keeps all data in one place and updates it in real time.

Use Barcode and QR Code Tracking

By labeling items, storage bins, shelves, or locations with barcodes or QR codes, teams can:

- Scan items instantly

- View item details immediately

- Reduce manual data entry

- Improve accuracy

Keep Inventory Data Centralized

When inventory information is stored online, teams can access it anytime and from anywhere.

This improves coordination, especially for businesses with multiple locations or teams.

Track Item History and Movement

Recording item movement, check-ins, and check-outs helps maintain accountability and prevents confusion.

How Tracmor Helps Improve Inventory Visibility

Tracmor is designed to make inventory visibility simple and clear.

With Tracmor, businesses can:

- Track inventory and assets online

- Organize items by category, location, and status

- Use barcode and QR code scanning

- View inventory details instantly

- Maintain accurate records and history

- Reduce time spent searching for items

Everything stays organized, updated, and easy to access.

Conclusion

Poor inventory visibility may seem like a small issue, but it has a big impact on daily operations.

It slows down work, increases errors, and creates unnecessary confusion.

By switching to a digital inventory tracking system, businesses can gain clear visibility, save time, and improve overall efficiency.

With Tracmor, inventory management becomes simple, organized, and easy to control — helping teams focus on their work instead of searching for items.